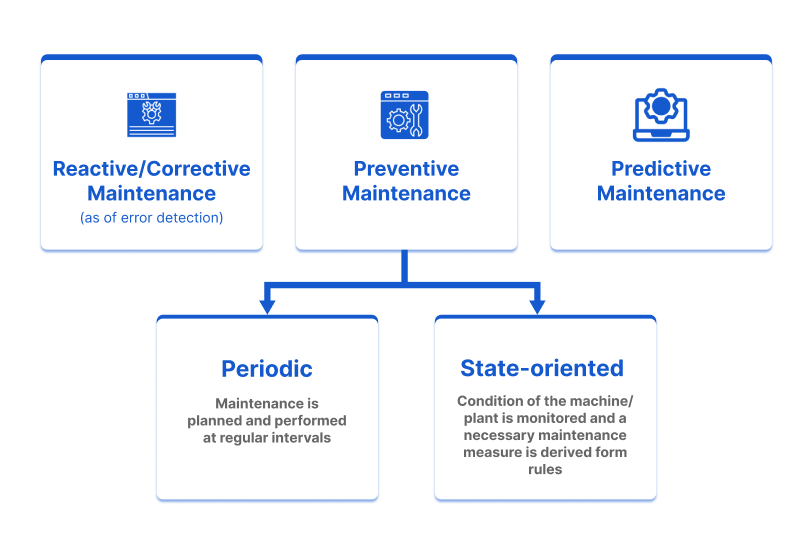

Corrective and Preventive Maintenance

Our Corrective and Preventive Maintenance (CPM) services are designed to ensure the optimal performance, reliability, and longevity of our clients’ equipment and facilities. We focus on promptly addressing immediate issues while proactively proposing solutions to minimize the risk of future breakdowns or disruptions. This approach is especially vital for mission-critical facilities, where maximizing performance and minimizing downtime are paramount.

Corrective and Preventive Maintenance

- Maintenance Support Structure

- Maintenance Support Assurance

- Annual Maintenance Contract Program

- Avoid Or Mitigate Consequences In Failure Of Equipment

- Preserve And Restore Equipment Reliability

- Training On Proper Usage Of Equipment

- Replace Worn Parts Before Fail

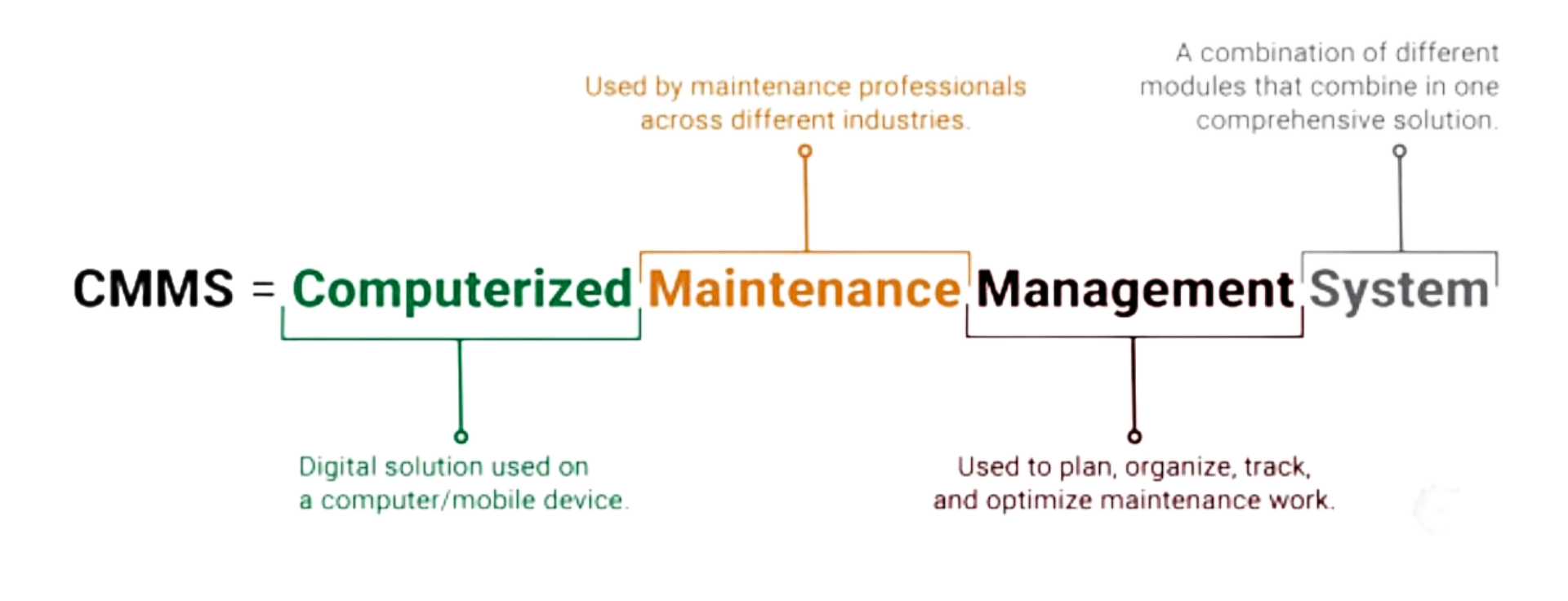

Computerized Maintenance Management System (CMMS)

Overall, our CMMS enhances operational efficiency, prolongs equipment life, and reduces maintenance costs, making it a valuable tool for businesses across various industries.

Inventory Management

Maintenance is planned and performed at regular intervals

Enhance Maintenance Planning

CMMS assist in scheduling Preventive Maintenance (PM) by providing reminders, list of work to do etc. With prompt PM carried out, it reduces unexpected breakdowns.

Cost Reduction

With prevention of breakdowns and optimization of maintenance schedules,CMMS indirectly reduce maintenance costs and extend the lifespan of equipment.

Increased Efficiency

CMMS streamlines work orders, communication, and documentation, leading to more efficient maintenance operations.

Data-Driven Decision Making

With data collected on equipment performance and maintenance history, Client can make informed decisions on management and resource allocation.

Historical Data Analysis

By storing the records over time with CMMS, Client able to analyze trends, identify recurring problems, and implement proactive measures to address them.

Standardization of Processes

Client can establish standard maintenance procedures, ensuring consistency and quality across all maintenance.

Feel Free to Contact us

for Any Enquiry

Thank you for visiting our webpage. To know more about our services, please use any of the following to contact us.

Puchong, Selangor

hybrid.sisb@gmail.com

+603-5882 8188